For demanding applications, our carefullyengineered resins capture the finest features in your model.

Our resins create accurate and robust parts, ideal for rapid prototyping and product development.

Perfectly smooth right out of the printer, parts printed on the Form 2 printer have the polish and finish of a final product.

Our Black Resin is specially tuned for models with very small features and intricate details.

Our Grey Resin has a fully matte finish, and shows details beautifully without primer.

Our White Resin emphasizes smooth surfaces and cleanliness, with a warm, slightly ivory color.

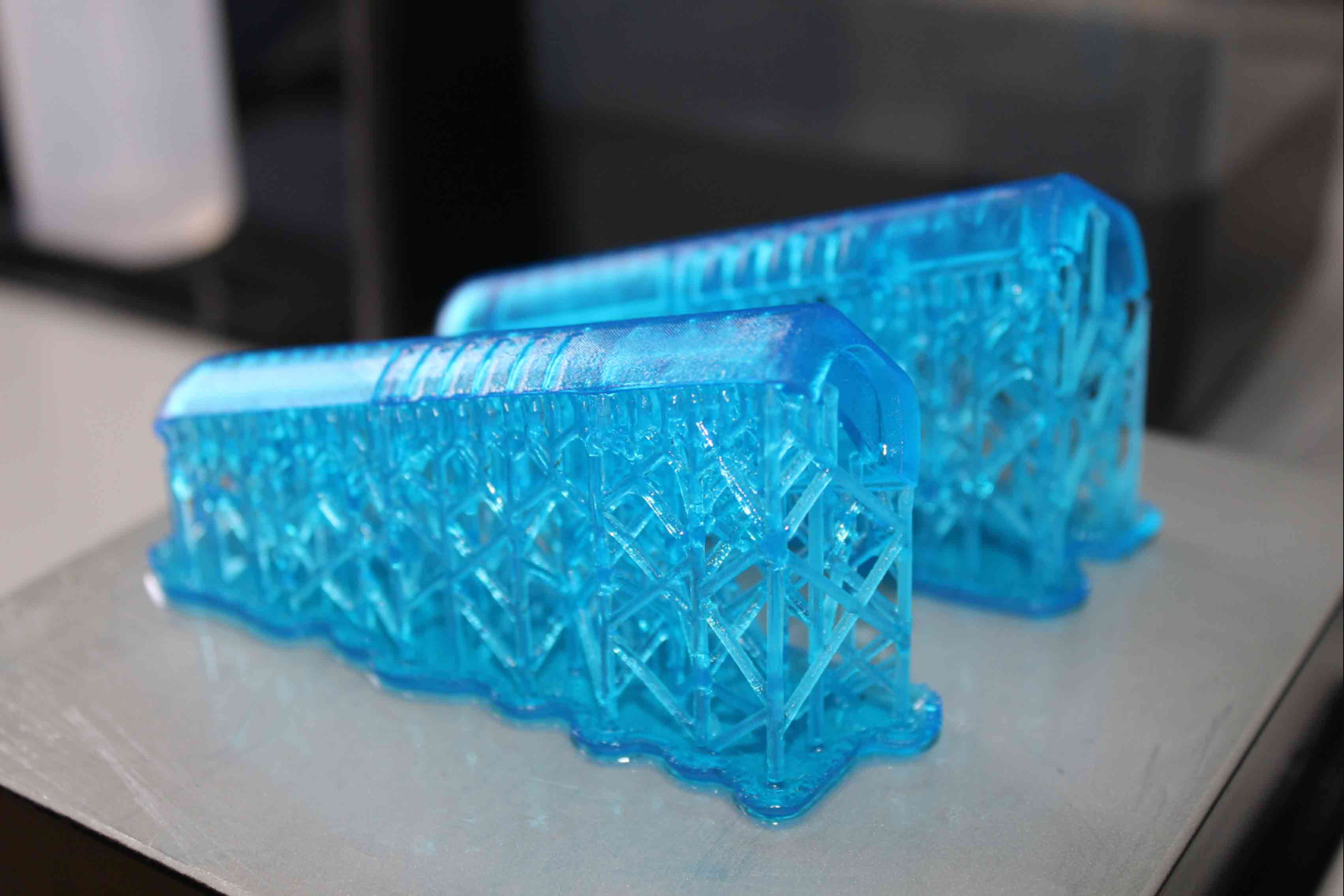

Our Clear Resin polishes to near optical transparency, making it ideal for showcasing internal features.

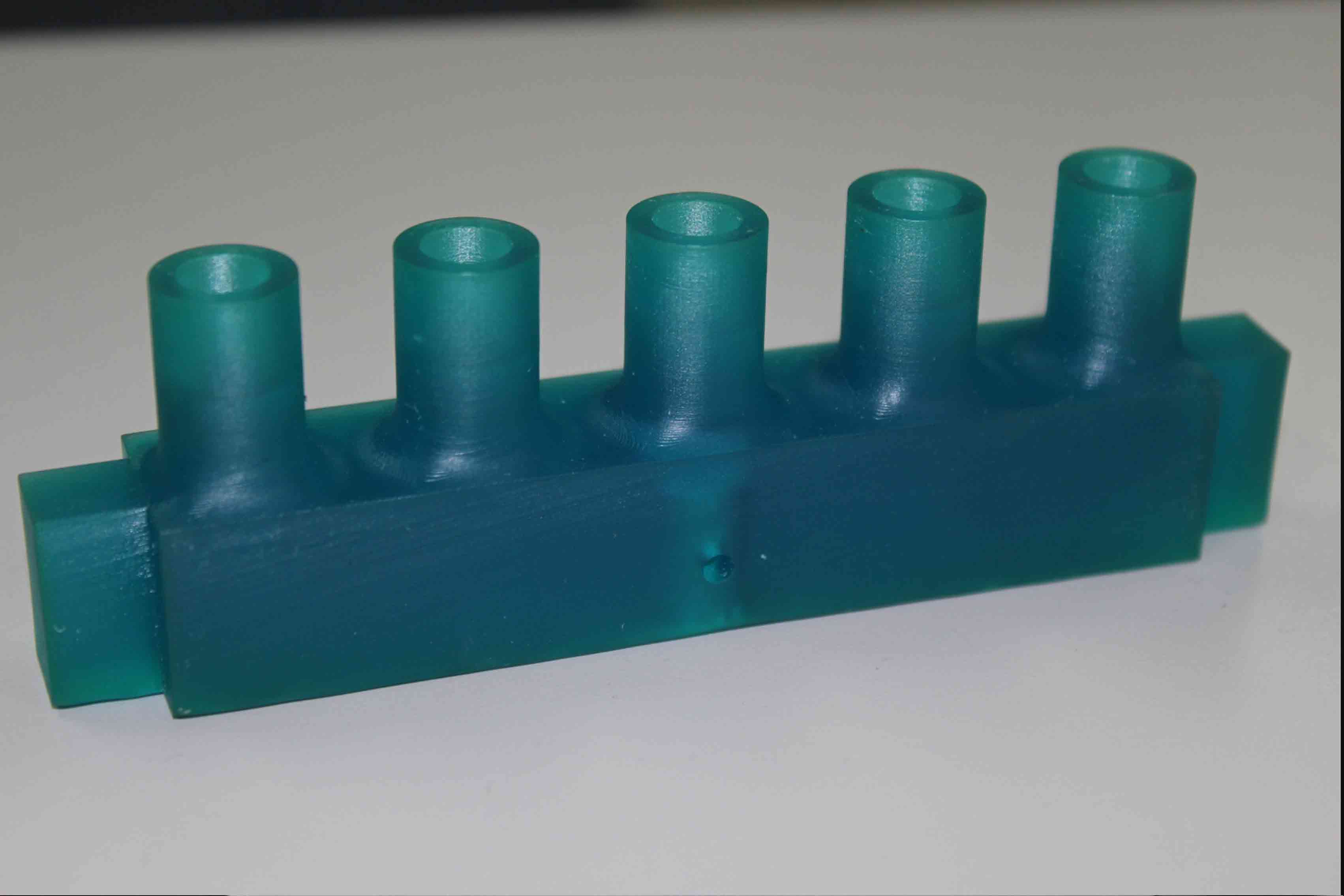

Our library of versatile, reliable Engineering Resins is formulated to help you reduce costs, iterate faster, and bring better experiences to market.

Designed to simulate ABS plastic, with comparable tensile strength and modulus. Perfect for functional prototyping and has been developed to withstand high stress or strain.

Simulates an 80A durometer rubber. Produce parts that need to bend and compress, especially over time. Excellent for simulating soft-touch materials and ergonomic features to multi-material assemblies.

High Temp has an HDT of 289 ºC @ 0.45 MPa — the highest on the 3D printing materials market. This material is great for static applications that will undergo higher temperatures. High Temp can also be used for production processes such as casting and thermoforming.a

Durable was designed to simulate polypropylene (PP) plastic, with comparable low modulus and high impact strength. Use this wearresistant, ductile material when parts require deformation and a smooth, glossy finish.